Groundwater level monitoring: Not as simple as it seems (1 of 3)

This is the first of three articles where we share some commonly overlooked issues that could impair your water level data and subsequent assessments, starting with datum choice. In other articles we’ll explore if your faithful water level dipper has had its day and look at other factors which may influence your results.

Water level monitoring is a doddle, right? Chuck one of those water level dipper tapes down a monitoring well until it goes “beep” and note the depth it says at the surface? Well, not really – in these days of millimetre accurate topographical surveys, we really should be able to consistently, precisely and accurately measure the depth to groundwater at a site.

Water level monitoring: Datum dilemma!

Following the installation of shiny new monitoring wells at our site (or even if re-using existing ones) we’ll need to know exactly where they are spatially, so employ the services of a topographical surveyor to provide co-ordinate (x, y) and elevation data (z), ideally to Ordnance Datum, but a site datum may also be used. We’ll assume metres above Ordnance Datum (m.AOD) for the rest of this article.

Here we are most concerned with the elevation of our monitoring well, so that when we measure the depth to water using a water level dipper we can calculate the elevation of the groundwater surface.

Water elevation (m.AOD) = Datum (m.AOD) – Depth to water (m)

With accurate and precise groundwater elevations across the site from numerous monitoring wells we can plot the groundwater surface over the site and derive hydraulic gradients, spot recharge mounds, cones of depression etc.

Always confirm with your surveyor what they are actually surveying when they provide an elevation for your monitoring well – it may be nearby “ground level”, the top of the headworks or manhole cover, the top of the internal well liner, the top of well cap, or the surrounding concrete pad for instance. If this is unknown then you’ve already lost the accuracy battle.

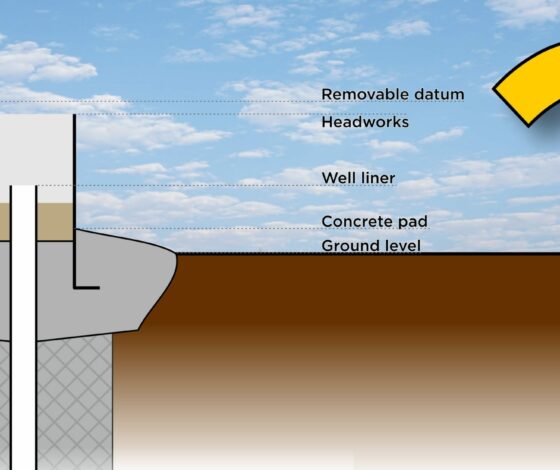

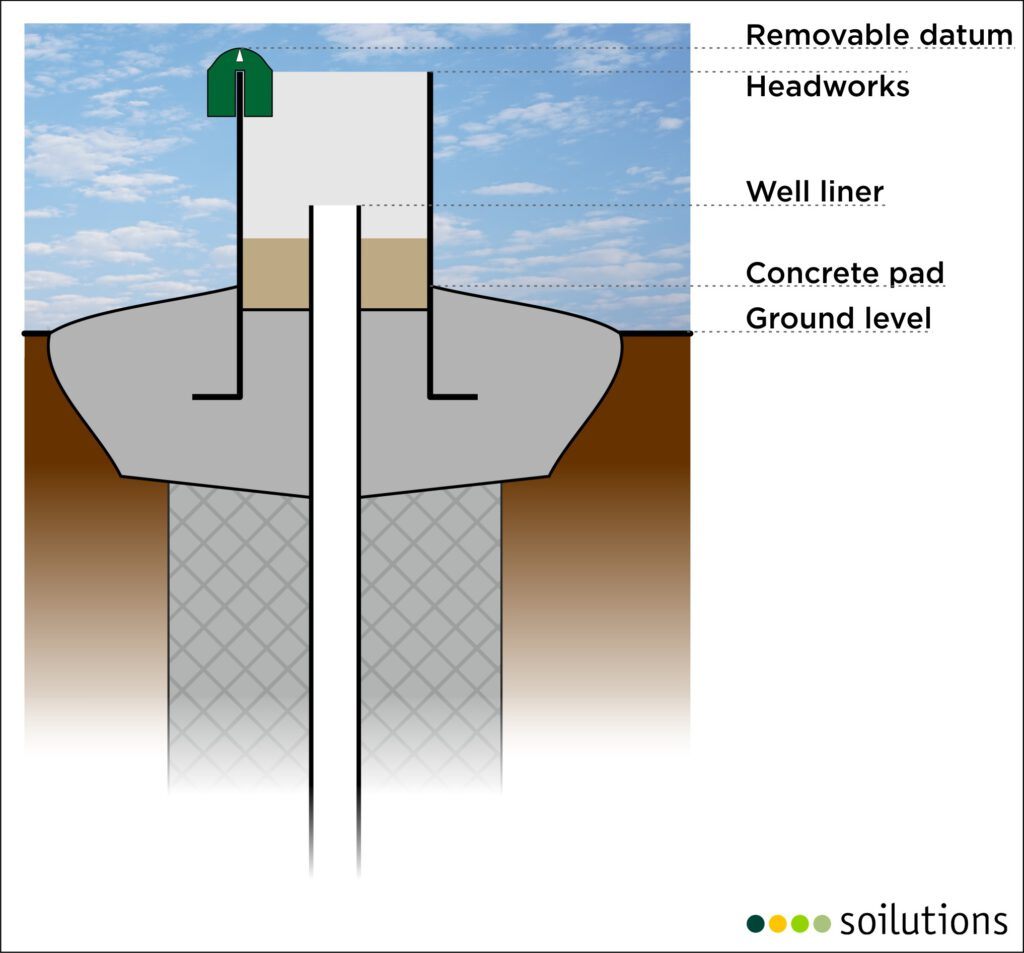

Let’s examine some of the datums commonly selected and discuss their pros and cons – the following image shows a cross-section through a typical above ground (“top-hat”) headworks and shows five common datums.

Removable datum

Pro

- Can protect dipper tape from friction damage on headworks

Cons

- Removable datum may get lost or forgotten for a monitoring round

- Removable datum may fit unintentional parts of headworks or well liner

- Likely to add additional length to measurement given its shape (and/or deviation from vertical)

Headworks

Pros

- Clearly visible

- Can be surveyed without unlocking or removing headworks

- Easily accessible

Cons

- May subside over time

- Lip is not vertically above the well – see deviation from vertical discussion below

- Likely to be affected by vehicle impacts

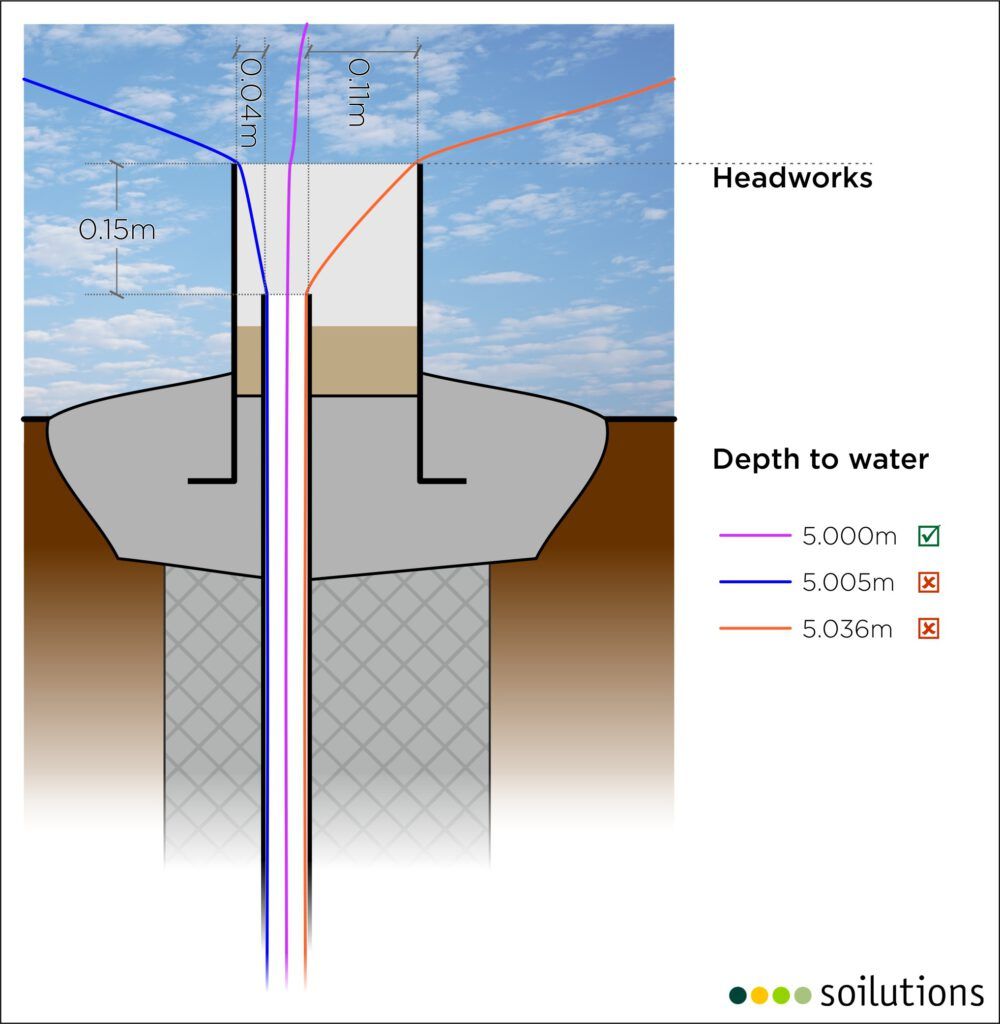

Deviation from vertical

The depth to water must always be measured with the water dipper tape being fully vertical. As the well liner is typically positioned in the centre of the headworks, it is tempting to use the headworks lip as the datum and thus introduce some additional (false) depth to the measurement, impacting accuracy. Where the well liner is not centrally positioned in the headworks, the choice of position on the headworks lip will also influence precision.

In the following example, some typical dimensions have been used to illustrate the impact of deviating from the vertical (not to scale).

The middle dipper tape presents the precise and accurate measurement of 5.000m, due to measuring over longer diagonals, or “deviation from vertical”, the tapes on the left and right would present measurements of 5.005m and 5.036m respectively – quite a variation.

Monitoring well liner

Pros

- Protected by headworks

- Less liable to subsidence

- No deviation from vertical

Cons

- If deep within headworks, accessibility and visibility may be reduced

- Liner tip may be cut at an angle

- Requires headworks to be removed to be directly surveyed

Concrete pad

Pros

- Clearly visible

- Can be surveyed without unlocking or removing headworks

- Easily accessible

- Less variable than soft ground

Cons

- Liable to subsidence

- Where liner is above level of pad, difficult to obtain precise measurement

- Deviation from vertical (see above)

- May or may not be same as “ground level”

Ground level

Pros

- Clearly visible

- Can be surveyed without unlocking or removing headworks

- Easily accessible

Cons

- Potentially variable and undulating in nature, subjective

- Where to measure on a slope?

- May change over time (erosion/deposition)

- Liable to subsidence

- Soft ground is deformable

- Where liner is above ground level, difficult to obtain precise measurement

- Deviation from vertical (see above)

Conclusion

At Soilutions we typically ask surveyors to provide elevation data for the top and centre of the headworks and use careful measurement to calculate the elevation of the top-most point on the well liner to use as datum. This is true for both “top-hat” headworks above ground and manhole headworks flush with the ground.

Whatever datums you select (or inherit) at a site, marking them permanently on each monitoring well will help ensure consistency (and therefore precision) of the collected monitoring data. The deviation from vertical can be avoided by placing a straight edge across the headworks and directly over the well liner to use as datum.

Leave a Reply